The Trent Side Channel Blower is a tough and reliable exhauster, incorporating the follow features:

Materials

Casings and impellers manufactured from quality aluminium alloy

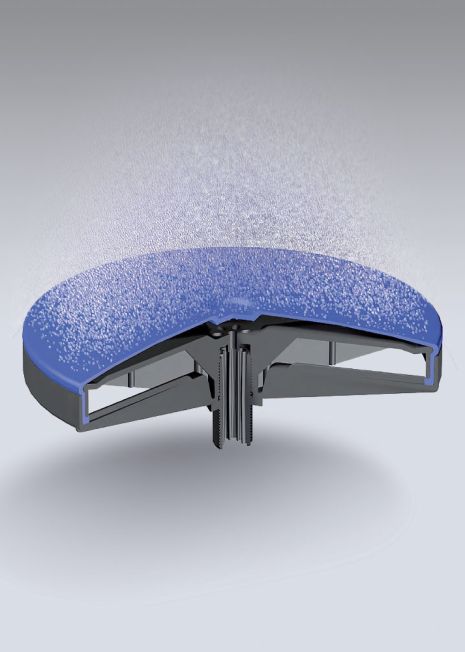

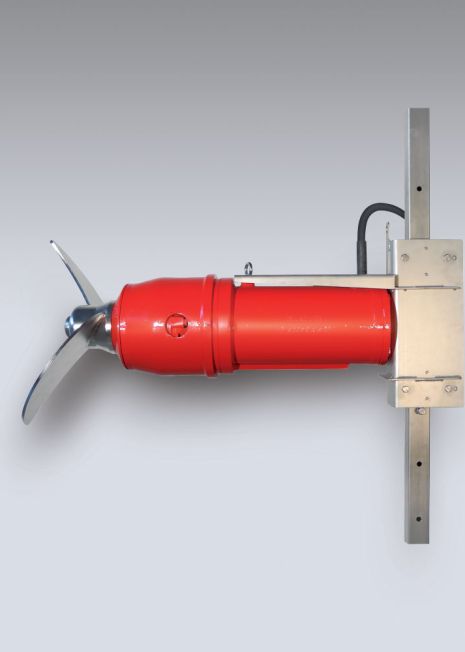

The standard machines for air are manufactured in the so-called ‘Close Coupled’ version; i.e. a flange mounted electric motor is bolted to the machine casing. The impeller, which is dynamically balanced, is fitted directly onto the motor shaft extension.

The two-pole electric motors, designed for continuous operation, are available in three phase or single phase up to 2.2 kW. They are manufactured according to EC specification

Meet the requirements of the European Directives 2006/42 (Machines), 2006/95 (Low Voltage), 2004/108 (Electromagnetic Compatibility) and of the applicable harmonised Standards.

For the handling of gases other than air, e.g. steam, industrial gases and mixtures of explosive gases, special gas tight units can be manufactured.

Applications & advantages

Trent side channel blowers are suitable for applications requiring considerably higher pressures than that which can be achieved using centrifugal fans. They’re also used for applications requiring an operating vacuum higher than the one achievable by a fan, but not as high as to require the use of a vacuum pump.

The rotating parts of the blower are not in contact with the casing, there is therefore no friction during operation and thus no internal lubrication is necessary. As a result the gas moving through the blower remains uncontaminated and completely oil-free.

The other main advantages of using side channel machines are:

- easy installation

- low noise level

- no vibration and therefore complete dynamic stability

- pulsation free discharge

- minimal maintenance

Manufactured under ISO 9001 certification, our Trent System also meet the requirements of the European Directives 2006/42 (Machines), 2006/95 (Low Voltage), 2004/108 (Electromagnetic Compatibility) and of the applicable harmonised Standards.

We also carry ISO certification for 14001 Environmental Management and 45001 for OH&S Management.

INSTALLATION

Installation is made easy using our step-by-step, plug and play, Installation and Maintenance Guide, supplied with your purchase.

MAINTENANCE

Maintenance is reduced to a minimum, with few moving parts within the blower system and with the use of hard wearing components. All regular maintenance information is outlined in the Installation and Maintenance Guide, provided with the product.