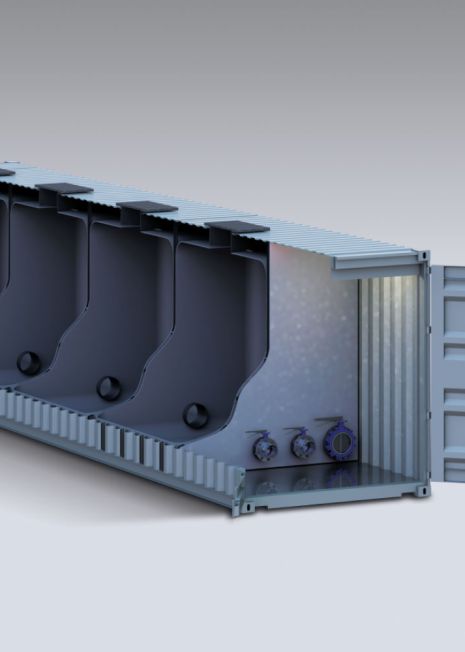

The Clearmaster Wash bay Tertiary Treatment System is conatinerised packaged plant, incorporating the following features:

TREATMENT SYSTEM

- Inlet pumpstation: Collection pit installed at the washdown pad. (Supplied separately).

- Coalescing plate separator: For the removal of suspended solids, free oils, and grease.

- Media filtration: To remove fine suspended solids at a high rate from water.

- Oil adsorbent granules: Treatment stage to remove emulsified hydrocarbons from the wastewater.

- Chlorine dosing: Flow paced chlorine dosing system for effluent disinfection.

- Pressure pump: 1 x pressure pump system delivering 0.5 L/sec @ 400 kPa. (1L/sec pump option also available).

- Control system: Integrated control panel for automatic operation.

KEY SPECIFICATIONS

- Power: 240 V, 50 Hz, 18 A

- Filtration: Down to 5-micron

- Controls: Auto/Off/Manual/Fully alarmed

- Dimensions: 6,000 x 2,500 x 2,600mm

CONTAINER ENCLOSURE

- Installed in a 20′ container, A grade quality

- Aluminium checker plate flooring

- LED control room lighting

- Twin roof mounted whirly birds

- Side grill ventilation, mounted on the doors

- Integrated floor waste

- GPO outlet

- Finished colour: Custom (Blue as standard)

KEY SYSTEM FEATURES

- Plug and play packaged system

- Proven and effective operation

- Compact skid design

- Can quickly gain local authority approval

- Full operator control via touch screen (remote monitoring option)

- Factory wet tested and approved

INSTALLATION

The Clearmaster system is a completely packaged plant, supplied directly to your site. Having been wet tested prior to dispatch, these system can be installed quickly, depending on the location and existing infrastructure on-site.

COMMISSIONING

Site commissioning is not included in our quoted price. Manuals, Operator check list will be submitted to the contractor or purchaser on deliver.

MAINTENANCE

Maintenance of all Clearmaster Systems should be undertaken in accordance with the User Manual. AKS offers a comprehensive Maintenance Service, including great value scheduled maintenance programs designed to extend the lifespan of your system.

Clearmaster Wash Bay products provide a cost-effective solution for wash bay developments of all sizes. Ideal for small equipment and cars, right up to trucks and large industrial vehicles, Clearmaster Systems meet all Australia’s strict local authority standards. Read more…