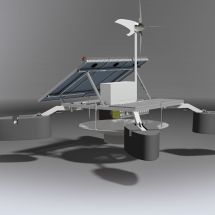

The Orb Solar Mixer draws water from the bottom of the reservoir and dispenses with a lateral ripple-flow action across an expansive water surface area. The Orb Solar Mixer incorporates the follow features:

Construction Materials

- Floats: Moulded Polypropylene

- Frame: 316 stainless steel

- Platform: Fibreglass

- Dish: Fibreglass

- Impellor: Stainless steel

- Bearings: Stainless steel, sealed type

operational systems

- Drive Control: High torque, low voltage motor, reversible, varible speed

- Flotation array: Hydro dynamaic design floats x 4, total buoyancy of 710kg

- Platform: Access step, suitable for 1 x 120kg operator

- Battery storage: Onboard triple x 12VDC, 120amp sealed deep cycle battery

- Solar array: On-board triple x 12VDC, 150W photovoltaic solar panels

- Status light: LED flashing light for operating status

- Draw tube system: 800mm diameter. 1-20m length, supplied standard 5m

- Charge protection: Temperature compensation charging system

- Fouling protection: Bird deterrent kit installed at top of solar array

OPTIONAL EXTRAS

- Certified lifting hooks

- Aluminium safety hand-rail powder coated

- SCADA control system

- 400W wind generator, stainless steel stand

SPECIFICATIONS

- Size: 4.5mSQ

- Weight: 385kg

- Min Operating Depth: 1.1m (Approx)

- Max Operating Depth: 30m (Approx)

- Induced Flow Rate: 1.3ML/hr (Approx)

- Combined Flow Rate: 2.5ML/hr (Approx)

- Solids handling: <100mm

- Origin: Made in Australia

Constructed from hard wearing rust resistant materials, the Orb Solar Mixer has been proven in the field over years of reliable service. Manufactured by AKS Industries under strict ISO 9001 standards and factory pre-commissioned. AKS also carries ISO certification for 14001 Environmental Management and 45001 for OH&S Management.

INSTALLATION

Due to the unique design of the Orb Solar and need to strategically position and tether the units within the water body, AKS Industries usually installs your Orb Solar Mixers for you. The installation cost is itemised in your product quotation. Should you wish to install your own unit or move an existing unit, please talk to your AKS representative.

Commissioning

All Orb Solar Mixer are pre-commissioned prior to dispatch from your factory, so no on-site commissioning is required.

MAINTENANCE

Maintenance is relatively straight forward with the Orb Solar Mixer, with few moving parts and with solar power operation, the unit can operate for long periods with any maintenance. Periodical maintenance is required however to clean the solar array and remove debris from the platform, water outlet dish and impeller. Other maintenance recommendations can be accessed in the User Manual.

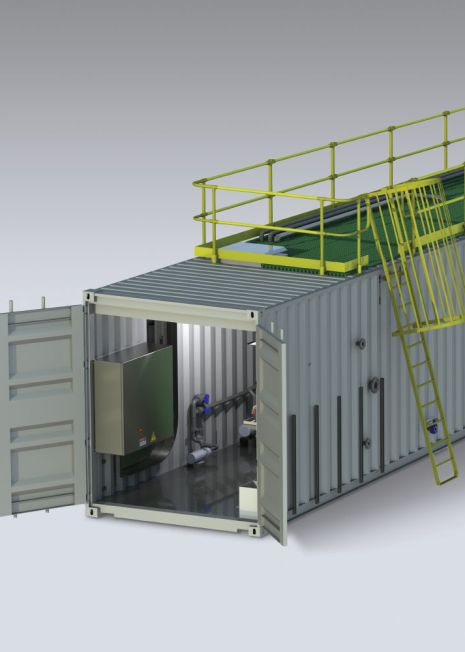

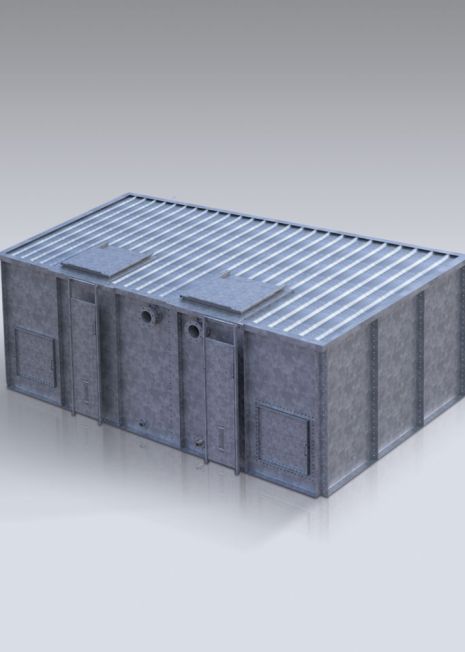

AKS Industries offers a range of water and wastewater mixers under the Orb Mixer brand name. Mixing technology plays an important role at the secondary treatment stage providing mixing and sludge suspension in tanks, ponds, ditches, dams and reservoirs.

Orb Mixers are available in a host of types, sizes and configurations, so there’s a Orb Mixer model suited to almost every conceivable application. Read more…